Cambridge 7th to 9th September

Presenting Author:

Tyra Oseng-Rees

<tyra.oseng-rees@uwtsd.ac.uk>

article posted 25 Apr 2015

Tyra Oseng-Rees

Tyra Oseng-Rees was awarded her PhD in Industrial Design in 2009. The research involved investigating into the properties of fused recycled bottle glass. The aesthetic features such as colour and texture development were key components during the investigation along with material testing such as third point bend test, stain test, photoelastic strain test, etc. A questionnaire was also conducted analysing its qualitative data regarding people's awareness and perception of recycled products.

Tyra was also commissioned by Grwp Gwalia to develop sustainable interior tiles which were installed at their sustainable development at the maritime Swansea Waterfront SA1 development.

Currently she is working to support the integration of sustainable design practice into the educational curriculum, design and manufacturing environment. Further research interests include collaboration with the architectural society and artists from any discipline developing new applications using recycled glass combined with other materials, meeting building specifications for indoor and outdoor installations.

Exploring the aesthetic potential for fused recycled glass

Tyra Oseng-Rees

Research, Sustainable Design, Swansea College of Art

University of Wales Trinity Saint David

ALEX Design Exchange, Alexandra Road,

Swansea, SA1 5DU

This presentation will explore the fusion of recycled bottle glass, its transition from a glassy to an opaque state and the opportunity it creates for interior glass installations and lighting. A paper published by Oseng-Rees & Donne (2015) demonstrated that randomly collected recycled bottle glass can be used by designers who wish to create architectural glass installations. The paper discussed the mechanical and photoelastic stability of the fused recycled glass material. This presentation will discuss the visual changes due to the devitrification process and illustrates its aesthetic opportunities that designer makers can use for interior light installations.

The process of fusing recycled bottle glass is by randomly collecting clear coloured bottles, jars and containers glass. The glass was cleaned by removing labels and glue residue and then crushed into smaller fragments. The crushed glass was then separated into various sized fragments named 0-2mm, 2-6mm, 6-12mm and above 12 mm. The glass fragments were then fused in a flatbed glass-kiln at various top temperatures ranging between 820 and 950 degree Celsius and held for 20 min before annealing.

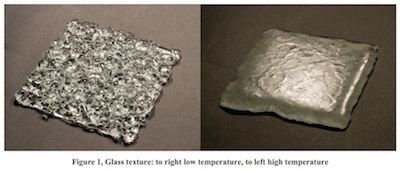

At the lower end of the temperature scale the glass was only softened and had an uneven surface whilst at the high end of the temperature scale the fused glass had a flattened surface. As seen in figure 1.

By extending the time the glass is held above 700°C in the kiln, the likelihood is that the glass will start to devitrify, also called crystallise. If the molten glass is allowed to cool slowly, the molecules in the fluid will have time to bond in a crystalline structure and it usually appears as a whitish scum on the surface of the top edge of the glass. (Beveridge, et al., 2005) By carefully controlling the type of container glass that goes into the glass mixture and the length of the fusion cycle, the recycled glass material can be controlled into either a transparent glassy texture to an opaque and semi-opaque texture, as seen on figure 2

By extending the time the glass is held above 700°C in the kiln, the likelihood is that the glass will start to devitrify, also called crystallise. If the molten glass is allowed to cool slowly, the molecules in the fluid will have time to bond in a crystalline structure and it usually appears as a whitish scum on the surface of the top edge of the glass. (Beveridge, et al., 2005) By carefully controlling the type of container glass that goes into the glass mixture and the length of the fusion cycle, the recycled glass material can be controlled into either a transparent glassy texture to an opaque and semi-opaque texture, as seen on figure 2

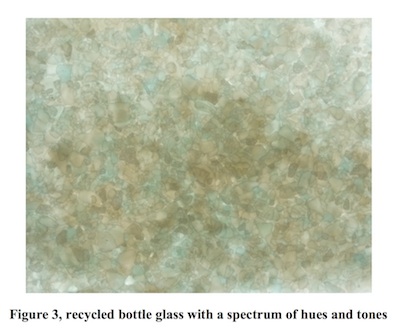

By carefully selecting bottles glass, subtle variations of colours between different bottles become apparent. Variations that were not visible in the glassy state become a spectrum of hues and tones when going through a devitrification process. This enables the creation of sheet glass that offers great potential to designers and glass makers and provides a use for material that otherwise is destined to become landfill or used as aggregates for the building industry, as seen in figure 3.

By carefully selecting bottles glass, subtle variations of colours between different bottles become apparent. Variations that were not visible in the glassy state become a spectrum of hues and tones when going through a devitrification process. This enables the creation of sheet glass that offers great potential to designers and glass makers and provides a use for material that otherwise is destined to become landfill or used as aggregates for the building industry, as seen in figure 3.

Bibliography

Beveridge, P., Domenéch, I. & Pascual, E., 2005. Warm Glass. A complete guide to kiln froming techniques, fusing, slumping casting. New York: Sterling Publishing Co, Inc.

Oseng-Rees, T. &apm; Donne, K., 2015. Innovation and development of a new recycled. Glass Technology: European Journal of Glass Science and Technology Part A., April.pp. 43-51.