Cambridge 7th to 9th September

Presenting Author:

Telesilla Bristogianni

<T.Bristogianni@tudelft.nl>

article posted 10 Mar 2015

Telesilla Bristogianni

Bristogianni Telesilla is a PhD researcher in Civil Engineering at the Glass and

Transparency Lab of TU Delft since 2014, focusing on structural cast-glass elements.

She has a background in architecture and building technology, with a specialization in

performance driven design and the development of novel building components with

the aid of parametric models and digital simulations, and supported by material

research and the production of physical prototypes.

Maximizing the Transparency of a Structural Glass Masonry Wall

Faidra Oikonomopoulou1, Telesilla Bristogianni2*,

Fred A. Veer3, Rob Nijsse4

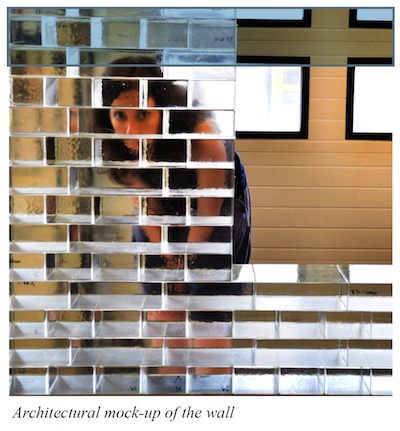

An adhesively bonded glass masonry system has been developed at the TU Delft

Glass and Transparency Lab for the Crystal House fašade, a completely transparent

reproduction of the previous, 19th century elevation in the historic centre of

Amsterdam, envisioned by MVRDV. In this paper, the steps followed towards the

materialization of the design and the maximizing of the transparency level of both

cast glass blocks and adhesive layer will be presented.

An adhesively bonded glass masonry system has been developed at the TU Delft

Glass and Transparency Lab for the Crystal House fašade, a completely transparent

reproduction of the previous, 19th century elevation in the historic centre of

Amsterdam, envisioned by MVRDV. In this paper, the steps followed towards the

materialization of the design and the maximizing of the transparency level of both

cast glass blocks and adhesive layer will be presented.

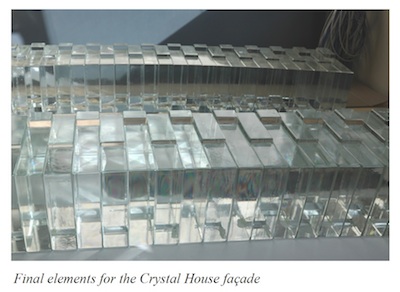

Regarding the glass blocks, the

optimization of the material's composition and production technique, as well as the

choice of texture and geometry played a key role in the visual result. The absence of

any metal substructure notably increased the overall transparency of the fašade.

However, it called for a transparent adhesive that could lead to a self-supportive wall

meeting the given structural requirements; at the same time it should result into

minimum visual distortion.

Regarding the glass blocks, the

optimization of the material's composition and production technique, as well as the

choice of texture and geometry played a key role in the visual result. The absence of

any metal substructure notably increased the overall transparency of the fašade.

However, it called for a transparent adhesive that could lead to a self-supportive wall

meeting the given structural requirements; at the same time it should result into

minimum visual distortion.

The family of Delo Photobond adhesives was chosen as it

fulfilled all the prerequisites. In particular, the type applied for the bonding of the

blocks is a clear adhesive with similar index of refraction to the glass used. The

ageing of the adhesive under sun exposure was also considered, to avoid eventual

undesirable colorations.

The family of Delo Photobond adhesives was chosen as it

fulfilled all the prerequisites. In particular, the type applied for the bonding of the

blocks is a clear adhesive with similar index of refraction to the glass used. The

ageing of the adhesive under sun exposure was also considered, to avoid eventual

undesirable colorations.

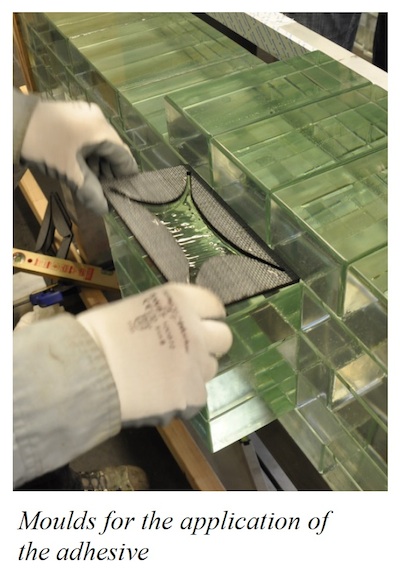

Moreover, the specific adhesive ensured the monolithical

behaviour of the bonded masonry with satisfactory flexural strength values. This

adhesive obtains its maximum strength when applied in a layer of 0.3 mm, thus very

strict tolerances in the brick sizes were necessary.

Moreover, the specific adhesive ensured the monolithical

behaviour of the bonded masonry with satisfactory flexural strength values. This

adhesive obtains its maximum strength when applied in a layer of 0.3 mm, thus very

strict tolerances in the brick sizes were necessary.

The application of the adhesive with special moulds and in relation to the acquired minimum tolerances of the glass blocks, led to the homogeneous distribution of the adhesive and the elimination of visible air gaps. Taking all the above measures into account, one can see through the structural 210 mm thick glass wall with minimum visual distortions.

Institutions:

1,3,4 TU Delft, Faculty of Architecture, Department of Architectural Engineering + Technology

2*,4 TU Delft, Civil Engineering and Geosciences, Structural Engineering Department

Email Addresses:

1 F.Oikonomopoulou@tudelft.nl,

2*T.Bristogianni@tudelft.nl

3 F.A.Veer@tudelft.nl,

4 R.Nijsse@tudelft.nl