Cambridge 7th to 9th September

Presenting Author:

Khouler Khan

<Khouler.Khan@soton.ac.uk>

article posted 6 May 2015

Khouler Khan

Khouler Khan received a B.Sc. Degree in Electrical and Computer Engineering from the University of the West Indies, Trinidad in 2003. He obtained and M.Sc. in Nano-electronics and mechanics from the University of Sheffield, United Kingdom in 2009 and is currently studying for his Ph.D. at the University of Southampton, United Kingdom. In 2004 he joined the Petroleum Company of Trinidad and Tobago in Trinidad as an Engineer and has worked on many large and small scale industrial projects in the Oil and Gas field. He now specializes in using his engineering skill set to build innovative automated system solutions to improve the manufacturing of high purity infrared transmitting materials. Over the past four years, Khouler has made significant progress on improving the quality and production methods of infrared materials at the Optoelectronics Research Centre under the EPSRC Centre for Innovative Manufacturing in Photonics. He is now a research fellow on the EPSRC Chalcogenide Amorphous Manufacturing Paternership (ChAMP) continuing to develop high purity systems for manufacturing chalcogenides.

Achieving low loss chalcogenide glasses

Khouler Khan, C Craig, P Bastock, E Weatherby, D Hewak

Optoelectronics Research Centre, University of Southampton, Southampton, SO17 1BJ

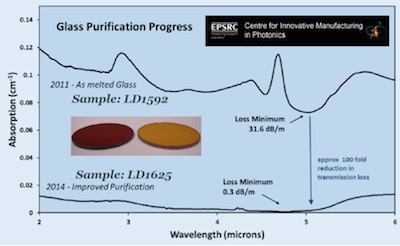

The authors report on the recent progress in making low loss infrared glasses, namely chalcogenides. A system completely fabricated in-house to make these functional materials is presented. With state of the art and novel components, we show the initial capability of this system to manufacture high purity materials. The focus in this case is on an emerging glass material, gallium lanthanum sulphide (GLS) which has potential for use in both active and passive infrared applications as well as numerous other non-optical devices. Chalcogenide glass is traditionally prepared by melt-quenching in a sealed ampoule. The process we have developed for GLS utilizes a controlled flowing argon atmosphere with various additional active gasses, to facilitate purification. This procedural control is essential to aid purification and allow reactive chemistry in order to achieve improved transmission properties. We report on the current capability of the system using impurity analysis and optical studies. This is one of the systems being used to produce high purity bulk glasses required for ChAMP.