Cambridge 7th to 9th September

Presenting Author:

Bridget Stewart

<bridget.stewart@mpiuk.com>

article posted 27 Apr 2015

Bridget Stewart

Dr Bridget Stewart is a Principal Scientist with the Materials Processing Institute.

She studied Chemistry at the University of Newcastle followed by a PhD Scholarship

in Glass Chemistry at the University of Aberdeen. Her PhD thesis, supervised by

Prof. John Duffy, concerned the optical basicity of sites for metal ions in oxide-based

glasses. The work was linked to metallurgical slags and she joined British Steel as a

slag chemist at the Scunthorpe Works before moving to the British Steel Research

centre in Teesside. She has since gone on to lead Corus's and Tata Steel's research

work in her specialist fields of continuous casting mould powders, as-cast surface

quality and oxide scale formation. This has included many international multi-partner

projects, with other research institutes, universities and steel companies in Europe,

which she has led as the Project Coordinator.

Dr Stewart spent two years as the Senior Lecturer in Materials Engineering at Teesside

University and combines her current role at the Institute with that of Visiting Lecturer

at Teesside. She is an Expert Evaluator in the Steel Area for the European Commission

and in 2011/12, she was President of the Cleveland Institution of Engineers (Affiliated

with IOM3).

Scattering light using glasses and crystals in order to optimise

the surface quality of continuously cast steels

Bridget Stewart (née Harris)

Materials Processing Institute, Eston Road, Grangetown,

Middlesbrough, TS6 6US, UK .

<www.mpiuk.com>

A target of all continuous casting operators is the ability to cast all grades free of surface defects.

Mould powders are key to the control of initial metal solidification and optimisation of

continuous casting mould operations. These powders are a mixture of several mineralogical

components and carbon. Typically they comprise

CaO, SiO2, Na2O,

Al2O3, F and C

with minor amounts of metal oxides such as MnO, Li2O,

MgO and Fe2O3.

A target of all continuous casting operators is the ability to cast all grades free of surface defects.

Mould powders are key to the control of initial metal solidification and optimisation of

continuous casting mould operations. These powders are a mixture of several mineralogical

components and carbon. Typically they comprise

CaO, SiO2, Na2O,

Al2O3, F and C

with minor amounts of metal oxides such as MnO, Li2O,

MgO and Fe2O3.

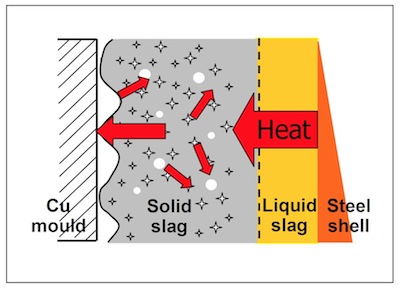

The powders are fed onto the surface of the molten steel, where upon they begin to melt,

forming first a sinter layer then a mushy layer and eventually a liquid flux pool.

Liquid slag from this pool infiltrates the gap between the mould and newly solidified

steel strand. Some of this lubricates the newly-formed steel shell. However, most of the

liquid freezes against the water-cooled copper mould, to form a slag film, which may

crystallise over time. The phase transformations and glass:crystalline ratio in this film

are critical to the rate of heat transfer from steel to mould. The aim of the mould powder

investigator is to tune the powder properties to suit the casting conditions and steel type.

The powders are fed onto the surface of the molten steel, where upon they begin to melt,

forming first a sinter layer then a mushy layer and eventually a liquid flux pool.

Liquid slag from this pool infiltrates the gap between the mould and newly solidified

steel strand. Some of this lubricates the newly-formed steel shell. However, most of the

liquid freezes against the water-cooled copper mould, to form a slag film, which may

crystallise over time. The phase transformations and glass:crystalline ratio in this film

are critical to the rate of heat transfer from steel to mould. The aim of the mould powder

investigator is to tune the powder properties to suit the casting conditions and steel type.

Traditionally, fluorine has been added in order to generate cuspidine

(3CaO.2SiO2.CaF2)

as the major crystalline phase precipitating from the predominantly

CaO-SiO2

glassy slag. However, fluorine has been found to have a detrimental effect on the

environment and equipment life. This paper discusses recent and current approaches

to optimising the scattering of radiation in order to control the rate of heat transfer,

with a focus on reducing the need for fluorine.

Traditionally, fluorine has been added in order to generate cuspidine

(3CaO.2SiO2.CaF2)

as the major crystalline phase precipitating from the predominantly

CaO-SiO2

glassy slag. However, fluorine has been found to have a detrimental effect on the

environment and equipment life. This paper discusses recent and current approaches

to optimising the scattering of radiation in order to control the rate of heat transfer,

with a focus on reducing the need for fluorine.